The neck block was glued from 2 pieces of 8/4 mahogany then cut a 14 degree cut made on the band saw, flattened on the jointer. Next a slot was ...

Merry Christmas to my friend and co-worker Kenny. I took this guitar from his workshop this last summer,it was in very rough shape. It needed a neck ...

My first scrolled head I'm going to use cedar for the sound board, found this piece at Home Depot Here is a practice honey bee ...

Using a homemade jig I made I find the location of the saddle. A strait edge showed me I'm low. The bridge is 3/8 of an inch, the strait edge ...

In my last blog I removed the neck on an old Harmony guitar now I'm going to remove the bridge. At some point someone ground down the top of the ...

I made this jig a few years ago and used it unsuccessfully maybe 3 times. What I missed was having the right size needle for steaming the joint ...

I've been thinking about turning pins and strap pegs for guitars.years ago I had a lath that my brother Tony gave me, but after moving a few times ...

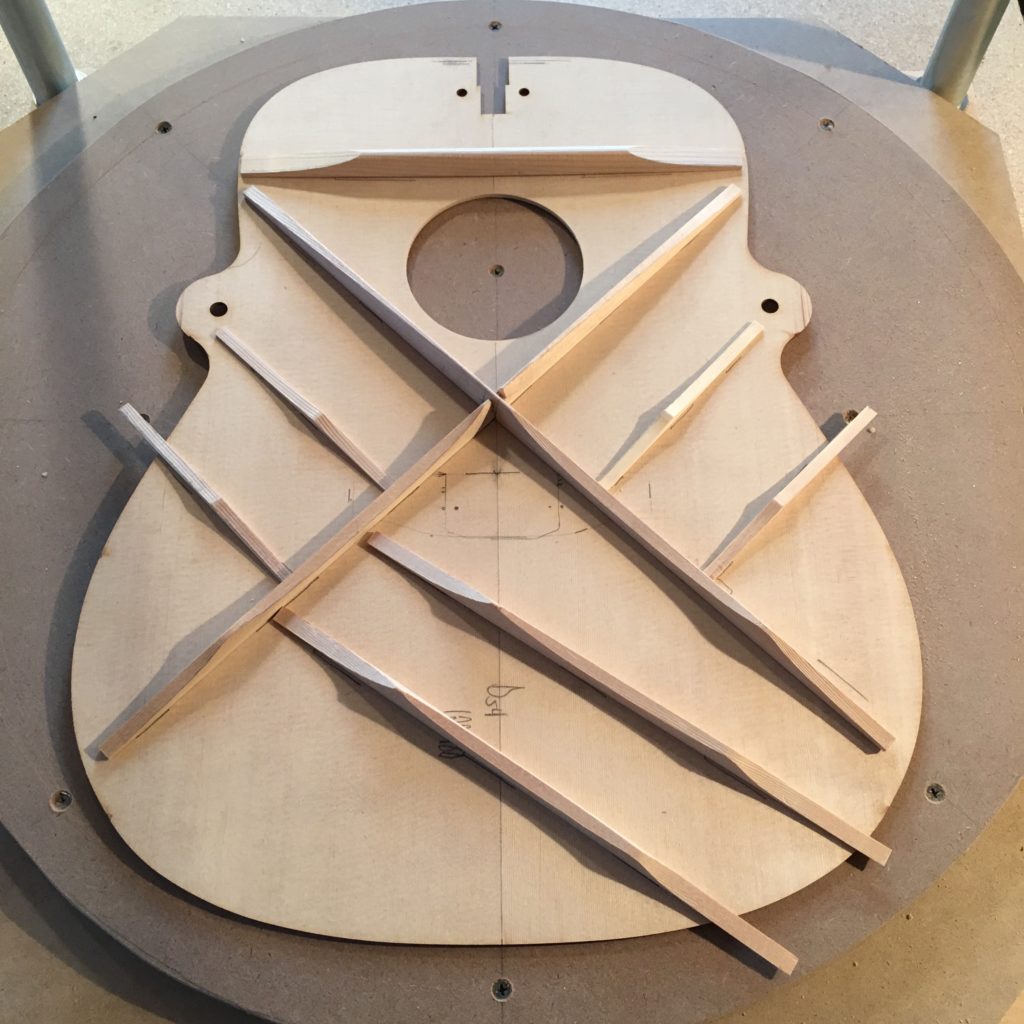

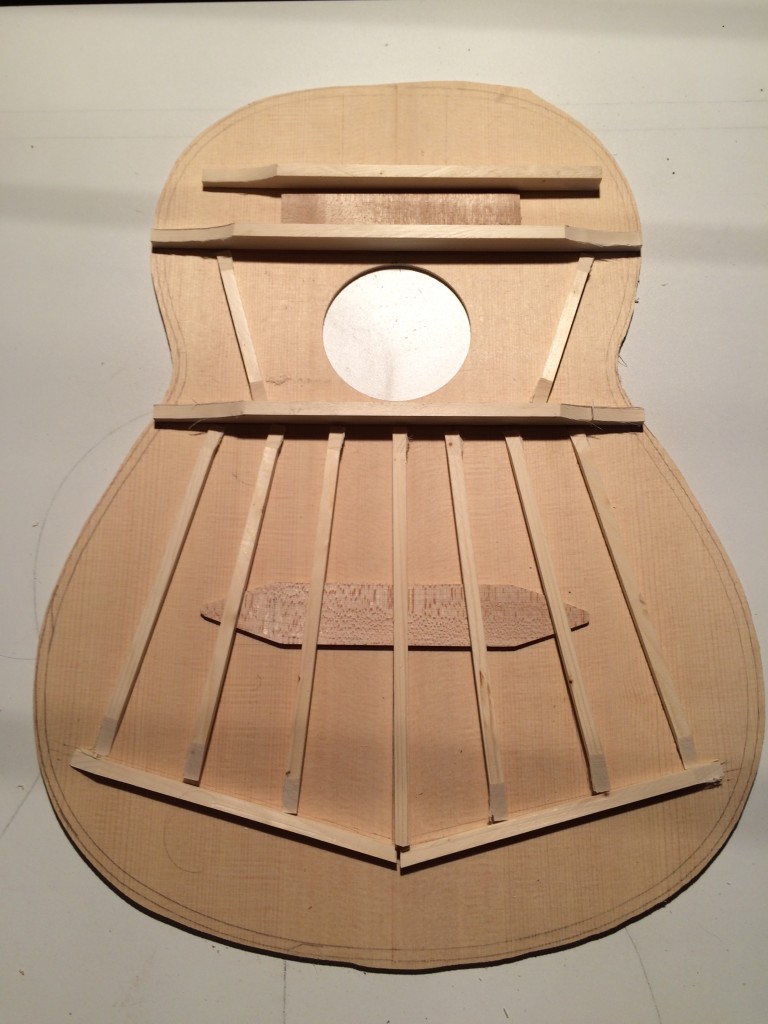

I'm sure there are many ways to make back braces but I have to go with what I know. I have now acquired some different soft woods , Sitka spruce , ...

Using the paper template that was used to glue back braces on, I made a halo template from 1/4 inch plywood. First used ...

After flush trimming the top to the sides, I will block sand with 80 grit sand paper to flatten and then 120 to smooth. Next ...

This is how they will dry. I’m just adding this to see if I can blog from my phone

Starting with a template and some wood bindings I got from the ASIA symposium. This is African Bubinga and the the blond wood is Avodire ...

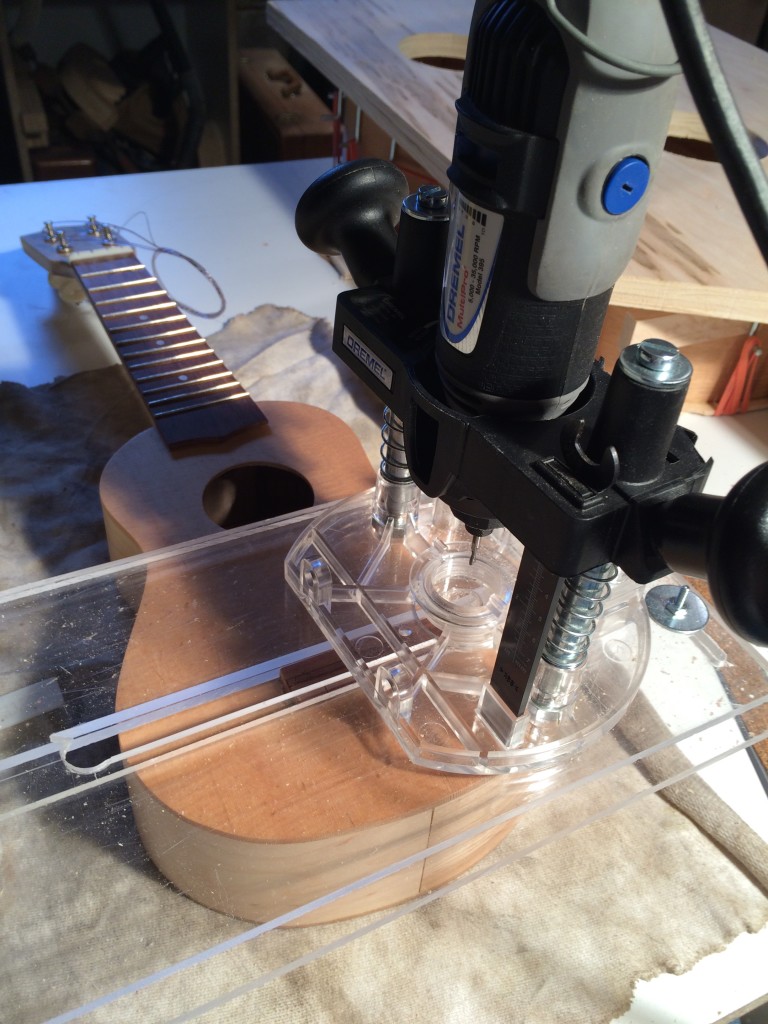

A 12 inch piece of Madagascar ebony. Ripped on the table saw I will get 6 blanks A plexiglass template and some blanks A small router ...

staring with a 25 foot radius someone made for me on a CNC machine . I lay the same pattern out on a piece of 3/4 and 1/4 MDF. using ...

Cut a rough shape out of 3/4 inch ply wood and mark out equal spaces for slots. Drill holes and band saw out slots and make a T ...

a pre cut set of braces bought on line, cost around $40. Traced out on 1/4 inch MDF. Using a small band saw cut out all the ...

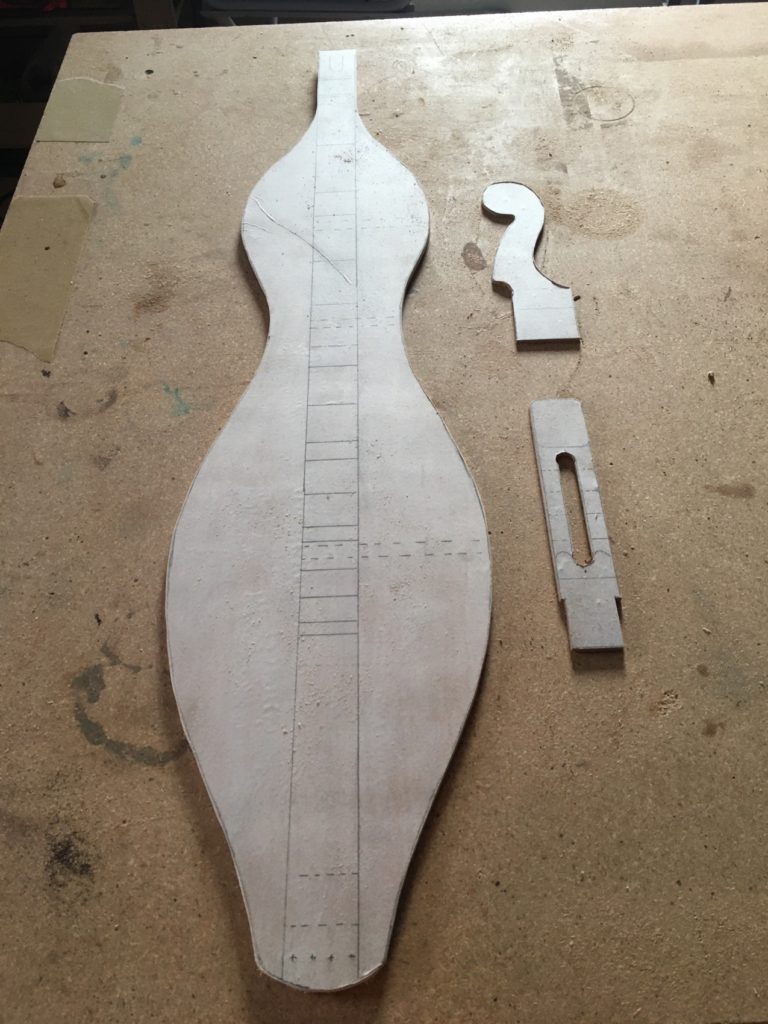

First I take a guitar that I like and trace an outline. Next band saw a template, sand to make a fair curve and lay out in 3/4 inch ...

Its been more than a year since I've posted anything on guitars. Im now sitting at a Word Press conference in Lancaster . Hopefully I will return ...

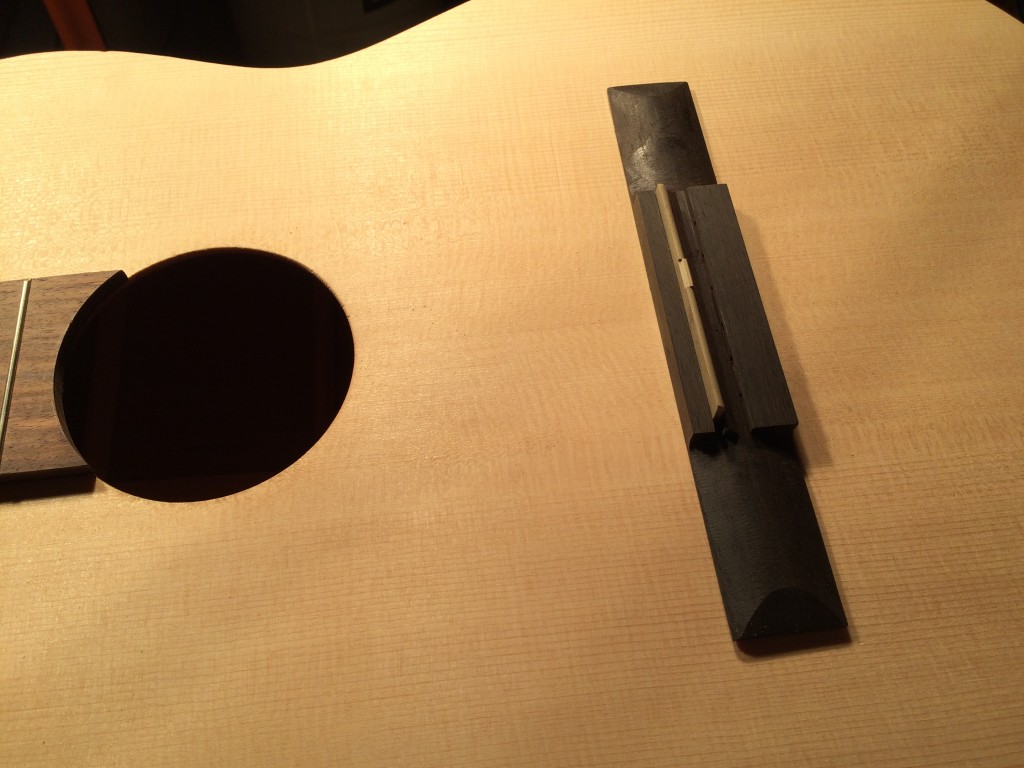

Starting with a piece of black ebony I bought from Woodcraft. Cutting the shoulders on the table saw. Make a slot on the table ...

While the fret board is still square,the fret slots are laid out and cut. The slots are recut to a stopped depth and checked with a ...

Saturday flea market. Left soprano ukulele, Right neapolitan mandolin,both need some work but I'm looking forward to restoring them ...

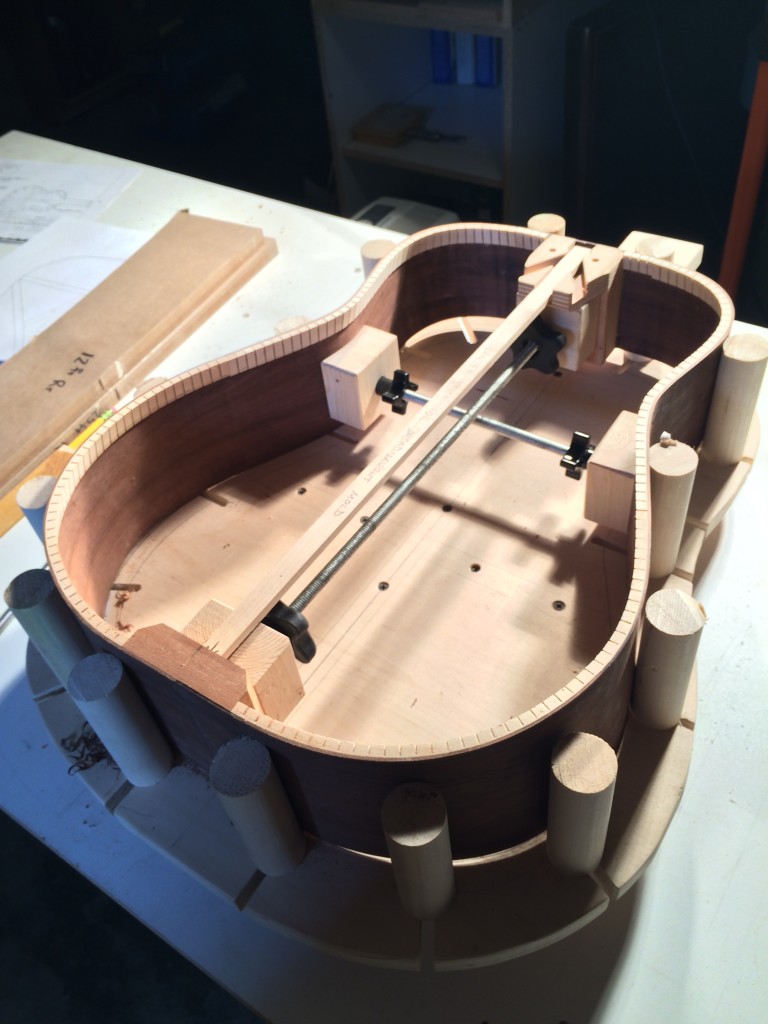

Body in form and glue is applied. Sound board is placed on top, centered and rubber bands used for clamping. The form is then ...

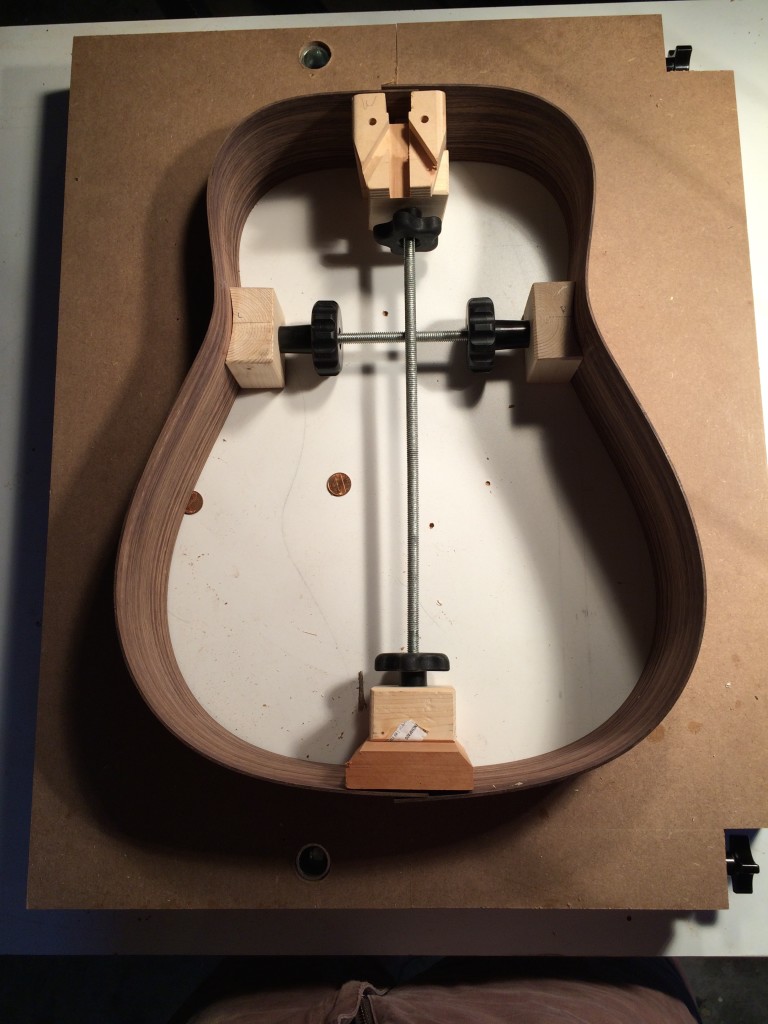

Drilled 2 5/8 inch holes centered on a piece of 6 x 12, 1/4 inch plexiglas. Very carefully! removed the waist on the table saw. Routed out ...

Lay out on 3/4 inch ply wood. I'm adding the neck to make sure i get the alinement nice and strait. The side is used to trace out ...

13/16 inch maple blanks and 1/4 inch aluminium bar Lay out 1 13/16 inch by 9 inch. Drilling mortis on drill press. Band saw jaw and lever, ...

Lay out. Roughing out softwood parts Trying to get the grain to run vertical. auxiliary fence Parts oversized with hardwood plates ...

Simple glue up jig instead of clamps. A small wedge is tapped into place on a flat surface glueing the two halves together. A template is used ...

Gluing the head and tail block Gluing in kerfed linings Dry and out of the form. Trimmed with the neck in place. The first half being ...

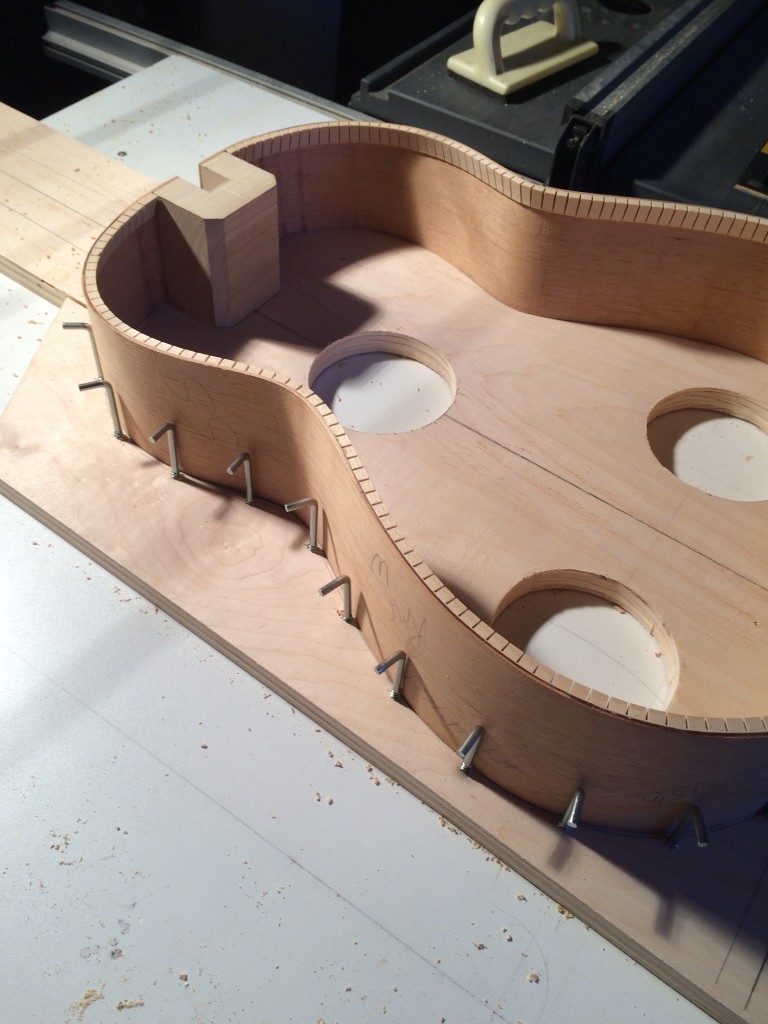

The work board is made of 2 pieces of 3/4 inch plywood and 1/2 inch bigger than the template.The matched side is made and both cut out for the head ...

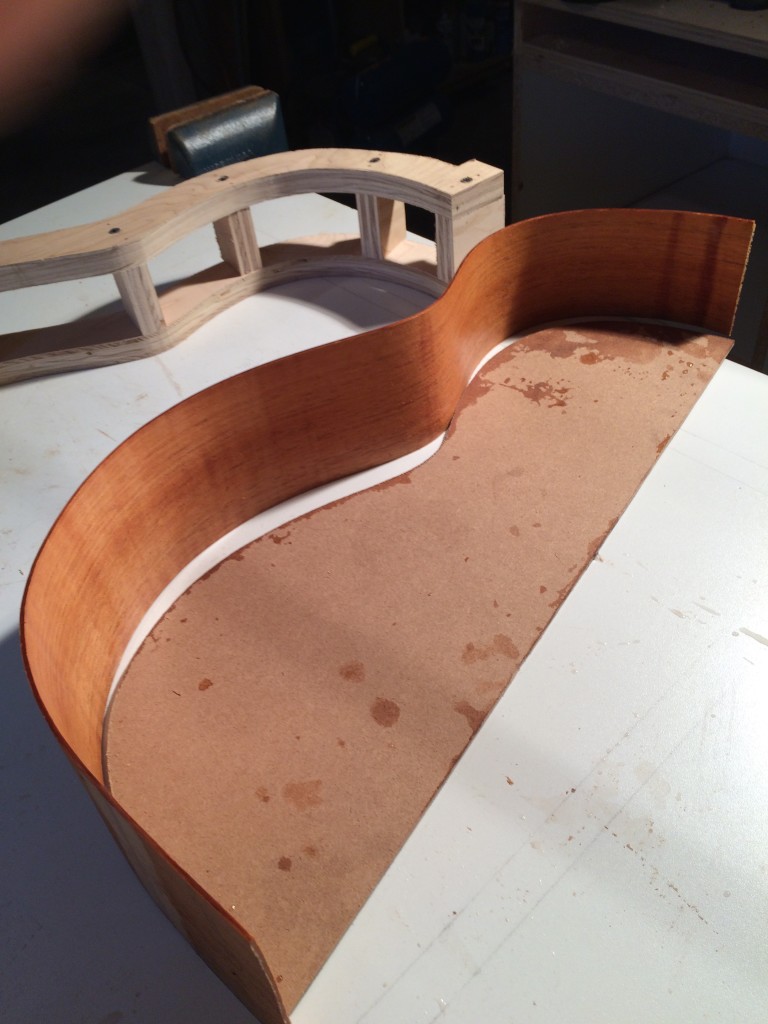

Homemade bending iron Forms templates and some bent sides Wetting the sides bending on the iron and shaping to the template. Clamped in the ...

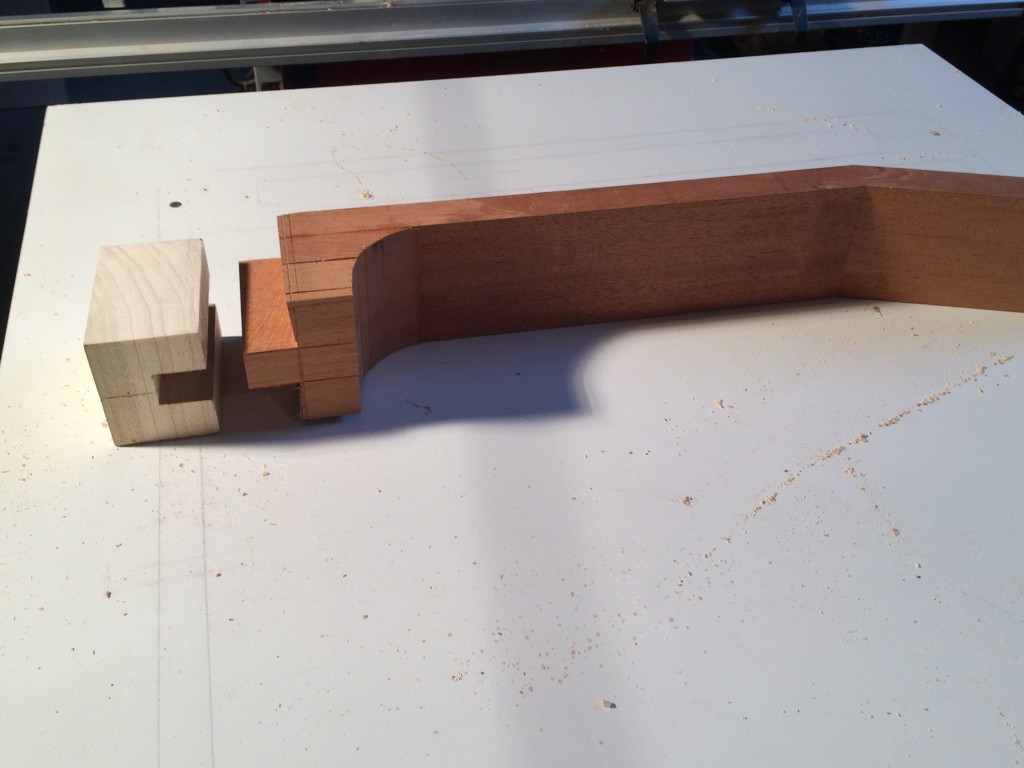

The neck blank with head block Layout and measurement Cutting the ramps,the plane was not used for this. Beveling the edge with a draw ...

The head block and the tenon on the neck blank. Sometimes it takes a long time to get what seems to be simple thing, done.The next time I do this I'm ...

Maple back and sides. stika spruce sound board and rose wood fret board. I got the rose wood from my brother Ed, he also has some old walnut that he ...

Resetting the neck, flattening the heal and new lower frets now I can put strings on. It may not have been played for more than 25 years, it ...

1930s parlor guitar, replaced the back with one purchased from Guitarmakers connection, the original north street factory at Martin guitar. we ...

Cigar box ukulele, my first instrument. The box is from Pennsylvania 1930s. I gave it to my nephew

I think it is early 1900s. Repaired the body and inlay work. The butterfly was a common